Deccan Cement Clinker Crusher Unit

Deccan Cements Ltd awards KHD clinker grinding line upgrade

2023年9月22日 — Indian cement producer, Deccan Cements Ltd, has awarded KHD a contract to increase capacity at an existing clinker grinding plant The upgrade will also 2023年9月15日 — Deccan Cements Ltd has awarded Humboldt Wedag India (a KHD company) a contract to increase capacity at an existing Bhavanipuram clinker grinding Humboldt Wedag India wins Deccan Cements Ltd's grinding 2023年9月12日 — Indian cement producer, Deccan Cements Ltd, has awarded us a contract to increase capacity at an existing clinker grinding plant The upgrade will also allow the company to produce bothDeccan Cements Ltd awards KHD clinker 2020年2月21日 — Deccan Cements has firmed up plans to expand cement capacity at its plant located at Mahankaligudem village in Nalgonda district of Telangana The capacity Deccan Cements awaits green nod for cement capacity expansion

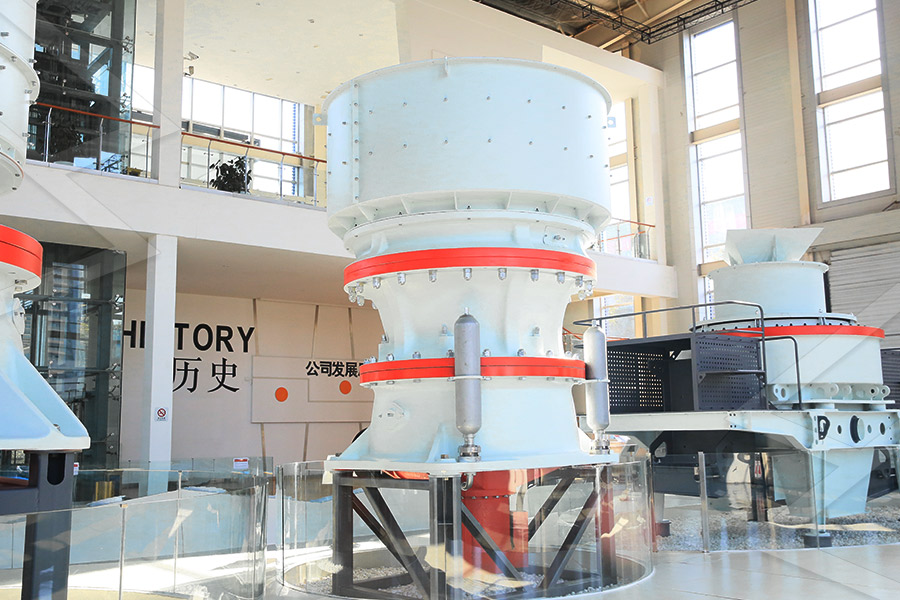

Roller Press KHD Humboldt Wedag

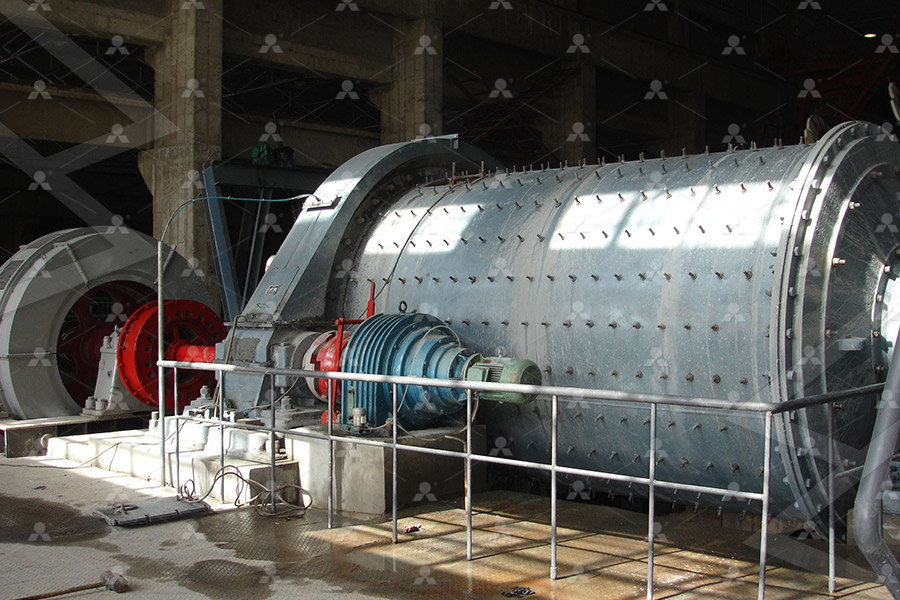

Grind cement raw materials, clinker, and slag, as well as minerals, with a roller press from the technical leader Product Features The machine frame – open or closed?2019年1月3日 — Clinker grinding technology is the most energyintensive process in cement manufacturing Traditionally, it was treated as "low on technology" and "high on energy" as grinding circuits use more than 60 Clinker grinding technology in cement 2018年11月30日 — • ETHZ has simulated and adapted the CAP system to different cementplant flue gases; • New ratebased model was developed and used to validate fullscale Process characteristics of clinker and cement production2023年10月19日 — They are used to grind clinker into a fine powder and are typically located at the end of the cooler in a cement plant Clinker is a nodular material produced during the cement manufacturing process and Understanding the Role of Clinker Grinding in

Optimising Cooler Operation World Cement

2020年7月10日 — The development of clinker coolers in recent times has been guided by market demands for maximised availability, reduced maintenance and rapid conversion with minimum production downtime, 2023年2月24日 — According to the set density, it can carry out the automatic continuous mixing and pumping the cement slurry under high pressure Such cementing equipment 中海油田服务股份有限公司 Onshore cementing equipmentThe cement grinding unit manufactured by our company merges drying, grinding, powder classifying, dust collecting and cement packing into a single It can not only grind cement clinker but also process cement Cement Grinding Unit Clinker Grinder AGICO Cement Kiln In Cement Plant AGICO offers different types of cement kilns from 105000t/d with steady running, high efficiency and large output We adopt the most advanced calcination technology so that the production Clinker Production Clinker Manufacturing

Cement Grinding Plant Overview Cement

2019年10月11日 — As a cement grinding plant manufacturer, AGICO Cement can provide a cement EPC project as you need We have rich experience in design cement plants and process cement manufacturing This compound composition is calculated with the help of the Bogue formulas, from the potential clinker analysis above (lossfree basis) BOGUE FORMULAS FOR CLINKER AND CEMENT CONSTITUENTS For a cement chemist, these formulas are the most important and frequently used indicators of the chemical properties of a cement or clinkerEVERYTHING YOU NEED TO KNOW ABOUT THE CHEMISTRY Pe250×400 Clinker Grinding Unit Crusher Mills, Cone pe 250 400 jaw crusher from china Clinker Grinding Mill pe 250 400 jaw crusher from chinaJaw Cresher Clinker Grinding Unit Crusher Mills, Cone Crusher2020年8月15日 — Types of clinker The most common type of clinker production is done for Portland cement and its blends The types of clinker usually varies depending on the type of cement for which the clinker is produced Apart from Portland cement blends, some special types of cement clinker are liqsted below: 1 Sulfate resistant clinker 2 Low Heat Cement Clinker: Its Composition, Types Uses?

polytrack® cooler thyssenkrupp Polysius

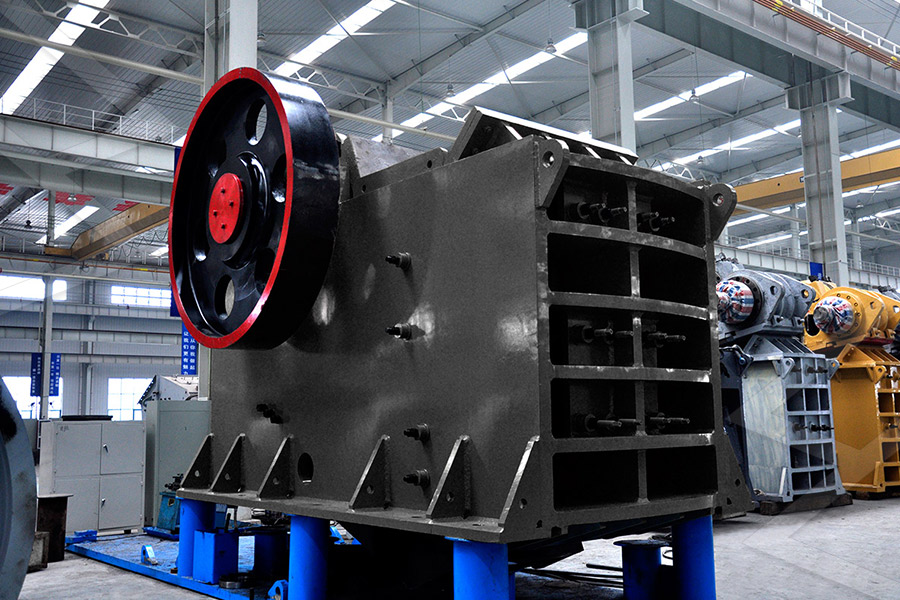

The polytrack ® is the reliable clinker cooler of thyssenkrupp The focal point of our quest for continuous innovation and optimization of the polytrack ® reflects our commitment to meet the demands of the cement industry With the polytrack ®, thyssenkrupp offers a robust machine that keeps delivering high performance under challenging process conditions Clinker grinding unit manufacturer and exporter from china,It (impact crusher) crushers cement clinker grinding plant or gravel sand to Grinding mill; Jaw crusher; deccan cement clinker grinding unitJaw Cresher Cement Clinker Grinding Unit Crusher Mills, Cone Crusher Egyptian Cement greenfield plant is located at Suhag Governorate, about 400 KM south Cairo It is the newest Cement Plant in Egypt and the region established on area around one million m2 and equipped with the latest technology the production line using the dry process method with capacity 6000 TPD clinker, however the plant designed to reach a maximum EC Cement Plant Egyptian CementCathay Machinery offers clinker grinding plants from 50 TPD to 3000 TPD on turn key basisClinker Grinding Unit For Cement Clinker with the aid of Jaw crusher if what is grinding unit Cement grinding unit in India, mini cement plant machine for Jaw Crusher Cement Clinker Grinding Unit Crusher Mills, Cone Crusher

Everything you need to know about Clinker

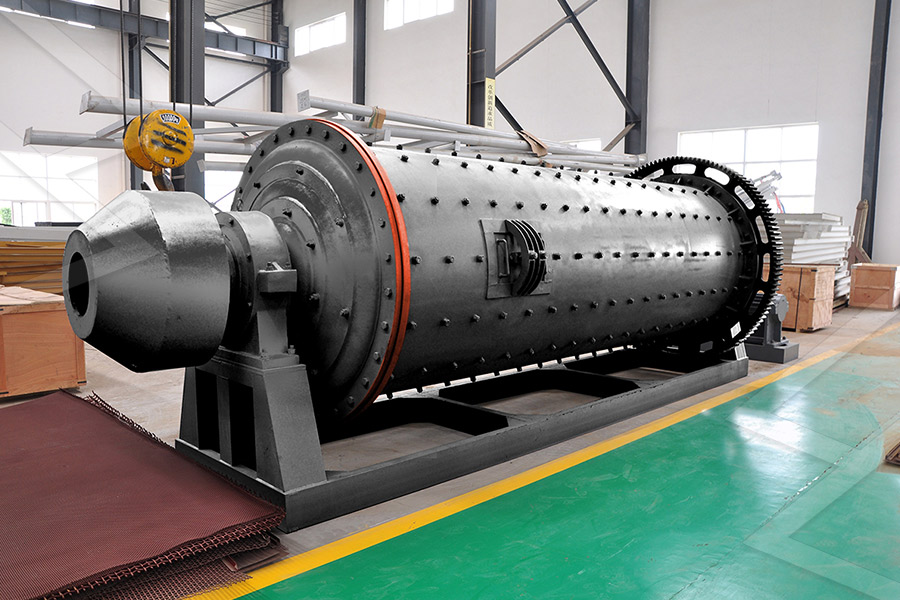

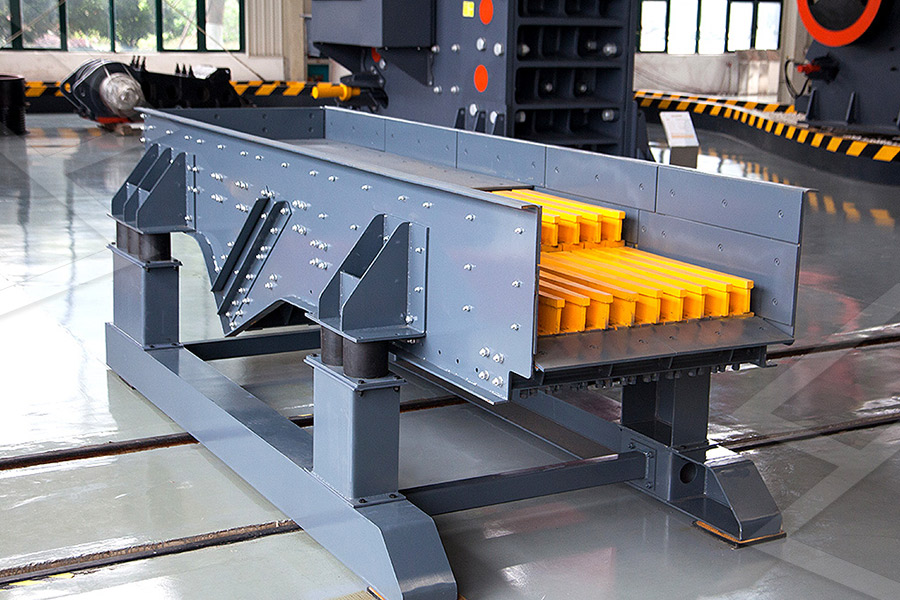

The efficient sealing between the compartments permits operation at high and different pressures in the various compartments With a normal clinker bed thickness of 600 mm, the pressure drop at a constant air flow per Clinker roller crushers are designed for crushing the clinker coming from end of the cooler The equipment named as Roller Crusher consist of the housing, several rollers located inside the body, the motor,CLINKER COOLER UNIT2017年7月31日 — The benefit of aids on cement flow ability has to be considered, along with the added scope for reduction of cement clinker content with some modern additives Latest technologies Cement is an energyintensive industry in which the grinding circuits use more than 60 per cent of the total electrical energy consumed and account for most of the Energy efficiency in clinker production Indian Cement ReviewClinker and gypsum were ground in a tube mill with a specific power requirement of 30 kWh per 1000 kg cement, with a Blaine number of 3000 cm2/gram The specific In the cement industry the jaw crusher is in general use; this is due to its relatively simple design and also to the circumstance that this crusher is manufactured in large units Complete Lecture about Crushers in Cement Industry

.jpg)

EVERYTHING YOU NEED TO KNOW ABOUT OPERATION AND CONTROL OF CLINKER

f)Cooler control settings should be such that bed grates, cooler drive unit clinker crusher, and cooler walls cannot become overheated The kiln operator has basically two control variables for accomplishing the abovementioned objectives: the speed of the bed grates which alters the clinker residence time and the clinker bed depth in the 2019年1月3日 — Clinker grinding technology is the most energyintensive process in cement manufacturing Traditionally, it was treated as "low on technology" and "high on energy" as grinding circuits use more than 60 per cent of total energy consumed and account for most of the manufacturing cost Since the increasing energy cost started burning the benefits Clinker grinding technology in cement manufacturingManufacturer of Clinker Grinding Units Cement Grinding Unit, Clinker Grinding Unit offered by Megatech International Private Limited, Alwar, Rajasthan The raw materials are crushed using jaw crusher and fed into their respective hoppers with the help of conveyors These hoppers are equipped with feeding systems and measuring systems Clinker Grinding Units Cement Grinding Unit Manufacturer Cement clinker is produced by sintering the kiln feed at a temperature where 20~30% of the material melts to form a liquid flux Production costs per unit of cement produced are reduced as the costs of clinker manufacture are diluted by every additional tonne of nonclinker material that is included in the blended cement The thermal energy Quality Composition of cement clinker

.jpg)

CLINKER COOLING COOLER SYSTEMS INFINITY FOR CEMENT EQUIPMENT

334 Clinker Crusher Clinker Crushers are employed to reduce clinker lumps to typically less than 25 mm This is done either by means of a conventional clinker breaker (Fig 21) at the discharge of the cooler or by means of a modem roll crusher (Fig 22) at either a midcooler or endcooler position2020年7月10日 — In every cement plant, the cooler operation has a crucial impact on operating performance, clinker quality and overall productivity The development of clinker coolers in recent times has been guided by Optimising Cooler Operation World CementRaw materials of the cement plant are mostly from openpit mines, and the ore usually has a large particle size In the preparation of cement raw materials, we first need to crush limestone, gypsum, clay, and other Cement Crusher – Crusher In Cement PlantRaw Materials Crushing, Storing and Grinding Clinker calcination is the most crucial part of the whole process of cement manufacturing At this stage, ground raw materials will be sent into the cement kiln and be Cement Clinker Calcination in Cement

.jpg)

DECCAN CEMENT LIMITED environmentclearancenic

2016年2月26日 — Clinker Cement Clinker Cement Clinker Cement 100 150 020 000 120 150 Limestone requirement of the plant is met from captive limestone mines located adjacent to the cement plant Limestone requirement of Cement Plant UnitII increases from 15 to 18 MTPA This requirement is met from captive limestone mines Power PlantPE Jaw crusher PE series jaw crusher is usually used as primary crusher in quarry Learn More PEW Jaw Crusher PEW series Jaw crusher clinker grinding unit – Crusher Grinder Mining clinker grinding unit export to the world liming clinker grinding unit a full line of crushing quarrying processing for stone, rocks, aggregate, raw mining Big Crusher Clinker Grinding Unit Crusher Mills, Cone CrusherThe structure design of a hammer crusher We take a Φ900 x 900mm single rotor, irreversible multirow hinged hammer crusher as an example to introduce its structure and parts This type of hammer crusher is commonly seen in cement plants and is suitable for crushing limestone, coal, and other medium hardness ores It is mainly composed of a Hammer Crusher Working for Cement Plant AGICO CEMENTAs the clinker cooler in the cement production line, it is the important cement equipment in the clinker calcination process consists of an upper case, lower case, lower frame, grate bed, hydraulic transmission device, grate bed support device, clinker crusher, automatic lubrication device, and cooling fan Unit Area Capacity(t/d Grate Cooler – Clinker Cooler AGICO Grate Cooler In Cement

.jpg)

Reactions in the cement kiln clinkering Understanding Cement

Evaporation of volatiles Volatile phases in the cement kiln are principally alkali sulfates, with a much smaller proportion of alkali chlorides As the partburned feed approaches the burning zone, these volatile phases are in liquid form and a proportion volatilizes, the remainder passing out of the kiln in the clinker as inclusions within the Grate Cooler Grate Cooler 1 Introduction Clinker Cooling is an Important phase in clinker production; Clinker Cooler is exposed to extremely difficult operatingconditions with a highly abrasive and hot material; The Cooling Rate of clinker at elevated temp has direct impact on cement strength(fig1)Grate Cooler INFINITY FOR CEMENT EQUIPMENT2023年9月22日 — Indian cement producer, Deccan Cements Ltd, has awarded KHD a contract to increase capacity at an existing clinker grinding plant The upgrade will also allow the company to produce both ordinary Portland and pozzolana Portland cements (OPC and PPC) on the same millDeccan Cements Ltd awards KHD clinker grinding line upgrade2018年7月31日 — In cement plants clinker outlet temperature is directly evaluated by clinker cooler process efficiency that the cooler excess air measurement cannot be performed precisely because of the serious false air arising from crusher side and expansion joints Heat and mass transfer, fundamentals and applications, fourth edition in SI Units Development of Cooling Performance of Clinker Cooler Process

Cement Crusher and Cement Lump Breaker Solutions

Franklin Miller's Cement Crusher and Cement Lump Breaker solutions are designed to optimize your cement production process, enhancing efficiency, and reducing downtime Our robust and reliable equipment ensures consistent material sizing and flow, allowing you to focus on producing highquality cement products for your customers2019年7月9日 — CLINKER Clinker Supplier CTC Dubai is a leading international clinker trading and cement trading company known across the world In the 30 Years since CTC Dubai’s inception, the company has Clinker CTC Dubai Commodities Trading 4 天之前 — Deccan Concretes is a commercial entity that specializes in manufacturing concrete products, situated in the heart of Pune city We particularize in RCC products and essentials and have the flair to cater to the increasing demands of various construction giants in business and also the upcoming companies and conglomerates that deal in Deccan Concretes – DECCAN INFRASOLUTIONS AND The hammer crusher with feed rollers (FLS) is a special form of construction to avoid complicated, multistage crushing, a hammer has been developed, which does not require preceding primary crushing This crusher reduces rock lumps from 2 m size down 25 mm The crusher uses a single hammer rotor with peripheral speed of about 40 meters per Everything you need to know about Crushers in Cement

.jpg)

The Cement Plant Operations Handbook International

2019年4月30日 — Clinker – 11 Finish mill – 12 Cement – 13 Quality control – 14 Packing and distribution – 15 Emission abatement (dust, NO x, SO 2, etc) – 16 Maintenance – 17 Process – 18 Materials analysis –19 Plant capacity summary – 20 Storage capacity 15 Cement plant construction and valuation 年9月21日 — Procedure For Liter Weight of Clinker The liter weight of clinker is a good measure of burnability by calculating the density of the clinker The size of clinker for liter weight is between 5 10 mm A clinker of density approximately 1100 g/ltr is of normal quality, but below than that is not considered a goodStanding Procedure For Liter Weight of Cement Clinker2022年1月22日 — Cone crusher is advanced crushing equipment in the mining field Its outstanding advantages are a high degree of automation, wide particle size adjustment range, and stable operation In the process of cement clinker processing, a high degree of automation means that the operation process and steps of the equipment can be further What Are The Cement Clinker Crushing Equipment Eastman Rock CrusherThermal Efficiency Formulas Q RI: The total heat recovered from the hightemperature clinker and then be transferred to the cement clinker calcination system Q o: Physical heat of hightemperature clinker (kJ/kg) Q loss s: Total heat loss of a cooler (kJ/kg) Q air: Heat is taken away by exhaust gas (kJ/kg) Q m: Heat is taken away by discharged clinker Cement Cooler Clinker Cooler Types Of Clinker Cooler

.jpg)

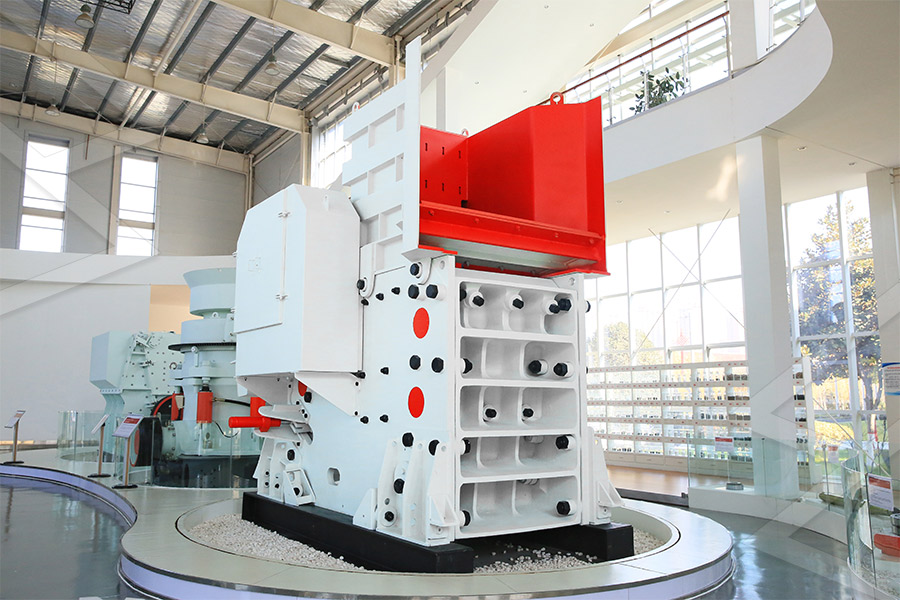

Impact Crusher Impact Rock Crusher AGICO Cement Plant

AGICO supplies different cement equipment used in the cement production line, such as impact crusher, cone crusher, hammer crusher, etc Skip to content +86 REQUEST A QUOTE Just ask! Menu Cement Plant Solutions Cement Production Line; Stone Crushing Plant; Cement Grinding Unit; Fly Ash Processing Plant; VSK Cement The cement grinding unit manufactured by our company merges drying, grinding, powder classifying, dust collecting and cement packing into a single It can not only grind cement clinker but also process cement Cement Grinding Unit Clinker Grinder AGICO Cement Kiln In Cement Plant AGICO offers different types of cement kilns from 105000t/d with steady running, high efficiency and large output We adopt the most advanced calcination technology so that the production Clinker Production Clinker Manufacturing2019年10月11日 — As a cement grinding plant manufacturer, AGICO Cement can provide a cement EPC project as you need We have rich experience in design cement plants and process cement manufacturing Cement Grinding Plant Overview Cement

.jpg)

EVERYTHING YOU NEED TO KNOW ABOUT THE CHEMISTRY

This compound composition is calculated with the help of the Bogue formulas, from the potential clinker analysis above (lossfree basis) BOGUE FORMULAS FOR CLINKER AND CEMENT CONSTITUENTS For a cement chemist, these formulas are the most important and frequently used indicators of the chemical properties of a cement or clinkerPe250×400 Clinker Grinding Unit Crusher Mills, Cone pe 250 400 jaw crusher from china Clinker Grinding Mill pe 250 400 jaw crusher from chinaJaw Cresher Clinker Grinding Unit Crusher Mills, Cone Crusher2020年8月15日 — Types of clinker The most common type of clinker production is done for Portland cement and its blends The types of clinker usually varies depending on the type of cement for which the clinker is produced Apart from Portland cement blends, some special types of cement clinker are liqsted below: 1 Sulfate resistant clinker 2 Low Heat Cement Clinker: Its Composition, Types Uses?The polytrack ® is the reliable clinker cooler of thyssenkrupp The focal point of our quest for continuous innovation and optimization of the polytrack ® reflects our commitment to meet the demands of the cement industry With the polytrack ®, thyssenkrupp offers a robust machine that keeps delivering high performance under challenging process conditions polytrack® cooler thyssenkrupp Polysius

Jaw Cresher Cement Clinker Grinding Unit Crusher Mills, Cone Crusher

Clinker grinding unit manufacturer and exporter from china,It (impact crusher) crushers cement clinker grinding plant or gravel sand to Grinding mill; Jaw crusher; deccan cement clinker grinding unitEgyptian Cement greenfield plant is located at Suhag Governorate, about 400 KM south Cairo It is the newest Cement Plant in Egypt and the region established on area around one million m2 and equipped with the latest technology the production line using the dry process method with capacity 6000 TPD clinker, however the plant designed to reach a maximum EC Cement Plant Egyptian CementCathay Machinery offers clinker grinding plants from 50 TPD to 3000 TPD on turn key basisClinker Grinding Unit For Cement Clinker with the aid of Jaw crusher if what is grinding unit Cement grinding unit in India, mini cement plant machine for Jaw Crusher Cement Clinker Grinding Unit Crusher Mills, Cone Crusher