Magnetic Separator Separating Machines For Ore Beneficiation

.jpg)

Magnetic separation: A review of principles, devices, and applications

Conventional magnetic separation devices are widely used for the removal of tramp iron from a variety of feed materials and for the beneficiation of ferrous ores These devices for separation of strongly magnetic materials employ a variety of mechanical designs2024年4月28日 — A magnetic separator is a widely used machine in manganese beneficiation It utilizes magnetic differences between minerals to separate magnetic Top 10 Manganese Beneficiation Machines for Efficient 2020年9月1日 — A novel lowintensity pneumatic planar magnetic separator designed to recover and concentrate finegrained magnetite minerals is investigated and the Assessing the performance of a novel pneumatic magnetic separator for 2020年7月27日 — Magnetic separation is a technology or process that exploits the difference in magnetic properties between the ore minerals and is employed to separate valuable Beneficiation of South African chromite tailings using

Integration of experimental study and neural network

21 小时之前 — Magnetic separation is a common procedure for the enrichment of magnetic iron ores Davis tube (DT) test is a standard laboratory technique used to determine the 2024年3月15日 — A novel fullscale centrifugal dry magnetic separator (cDMS) was developed, and in this investigation, it was used to process a fine magnetite ore, which Development of a centrifugal dry magnetic separator for 2020年1月12日 — This work reviews 24 studies on the magnetic separation of manganese ores; 6 of these studies report both a sufficiently high Mn grade (>44% Mn) and Mn/Fe A review of the beneficiation of lowgrade manganese ores by magnetic A magnetic separator featuring high magnetic field values, high field gradients, and large flow capacity has been applied to problems in mineral beneficiation The major effort has High gradient magnetic separation applied to mineral beneficiation

.jpg)

Physical Concentration of Heavy Minerals: A Brief Review on

2023年12月12日 — The efficacy of magnetic separation techniques on HMs has been studied The choice selection/application variation of the physical beneficiation 2017年10月24日 — Where the ore is different and challenging, we bring innovative capabilities to design new and unique solutions that augment and lift the potential of conventional flowsheets to extract the ore Plant Design Extending beyond traditional spiral plants our designs incorporate gravity, magnetic and electrostatic beneficiation Your iron ore beneficiation solutions Downer Group Site2020年3月20日 — The relevance of the paper is that dry magnetic separation (DMS) is the main beneficiation method of magnetite ores The lack of efficient industrialgrade machines and apparatus for separating finegrained magnetite ores means that DMS is used mainly as a preconcentration operation for fairly large classes The aim of the research is to study DRY MAGNETIC SEPARATION OF MAGNETITE ORES2024年9月7日 — Our factory professional produce different type Magnetoelectric Separator over 30 years The products includes dry type magnetic separator, wet type magnetic separator, electrostatic separator 40200tph Mine Ore Mineral Beneficiation Plant

.jpg)

Assessing the performance of a novel pneumatic magnetic separator for

2020年9月1日 — In another study, Ezhov and Shvaljov (2015) used a laboratoryscale EVS10/5 magnetic separator for dry beneficiation of iron ore of the Backer deposit This was done by analysing the influence of the current strength in the electromagnet winding of the magnetic separator on concentrate yield and recovery5 天之前 — Manganese ore magnetic separation is widely used to separate valuable from gangue minerals It uses the magnetic differences between various minerals to separate them Applying a magnetic field to a mixture of ore and gangue minerals attracts magnetic particles to the area, while nonmagnetic particles are repelled or pass through unaffectedFive Kinds Technology Of Manganese Ore Beneficiation2024年9月22日 — Automatic Magnetic Flotation Separators Iron Ore Beneficiation LONGi's Automatic Magnetic Floatation Separators have been been found to be able to regularly upgrade the grade of, some concentrates, by a factor of 29% greatly upgrading the quality of the end product This makes for a highly efficient and inexpensive way to upgrade your Automatic Magnetic Flotation Separators Iron Ore Beneficiation5 天之前 — Sometimes there are many iron impurities, in order to reduce the content of iron impurities, the magnetic separation method can be used for treatment The magnetic separation equipment is a permanent magnetic drum magnetic separator, a wet strong magnetic plate magnetic separator, and a vertical ring high gradient magnetic separatorProgress of Five Spodumene Beneficiation Methods JXSC Machinery

.jpg)

Process and Principle of Magnetic Separation of Iron Ore

Magnetic separation is a beneficiation method that uses the magnetic difference between minerals in a nonuniform magnetic field to separate different minerals Magnetic separation is the most commonly used beneficiation method for ferrous metal ore such as iron ore It is divided into weak magnetic separation and strong magnetic separation 2021年6月11日 — Mineral processing methods are mainly divided into two categories, namely physical mineral processing and chemical mineral processing Physical Mineral Processing Physical beneficiation includes magnetic separation, gravity separation, electrostatic beneficiation, friction beneficiation, particle size beneficiation, shape beneficiation, Guide of Mineral Processing Methods: 3 Main Beneficiation2023年3月9日 — Magnetic separators are widely used in the beneficiation of ferrous metal ores, nonferrous and rare metal ores; the recovery and purification of media in heavy media beneficiation; the removal of impurities from nonmetallic ore raw materials; the removal of ironcontaining impurities in crushing; recycling scrap steel from smelting waste residue Magnetic Separators For Mineral Processing JXSC Mining2023年3月13日 — 2 Magnetic separator Magnetic separator can recover useful magnetic minerals contained in copper ore It can improve the taste of ore and the utilization rate of resources, and reduce the waste of How to Process Copper Ore: Beneficiation

.jpg)

Magnetic Separation Technology for Mineral

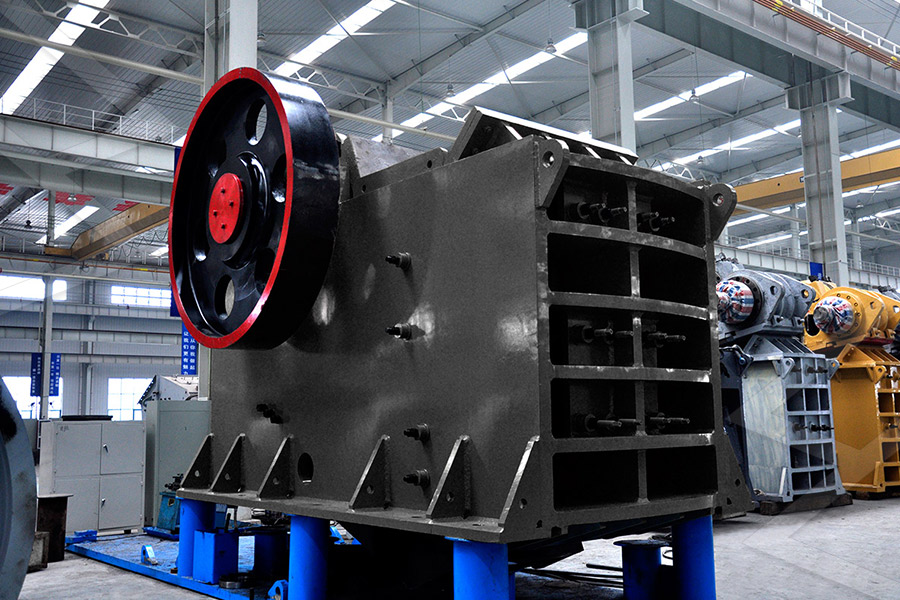

2024年5月9日 — Magnetic separation technology plays a pivotal role in mineral processing, offering efficient and versatile solutions for separating valuable minerals from gangue materials By harnessing the magnetic 2022年3月22日 — Here are the 10 types of most popular iron ore beneficiation machines Model : Function : Capacity : Price : PE Jaw crusher : Coarse crushing : 12200 t/h : Magnetic separator : Separating : 10 10 Most Popular Iron Ore Beneficiation 2020年9月1日 — The application of dry processing technologies in iron ore beneficiation is a topical area of research Song et al (2019) investigated the use of a fluidised dry magnetic separator to purify and recover magnetite powder from a mixture of magnetite powder and coal powder and concluded that the fluidised dry magnetic separator can improve the Assessing the performance of a novel pneumatic magnetic separator for 5 天之前 — Gravity separation concentrate is magnetically separated by induction roller strong magnetic separator to separate ilmenite and monazite magnetic impurities After magnetic separation, nonmagnetic products are preheated in the hopper to above 60°C, and then electrostatic platetype highvoltage electric separation is used to obtain high Breakthrough In High Grade Rutile Beneficiation Method

A Novel Pneumatic Planar Magnetic Separator for Magnetite Beneficiation

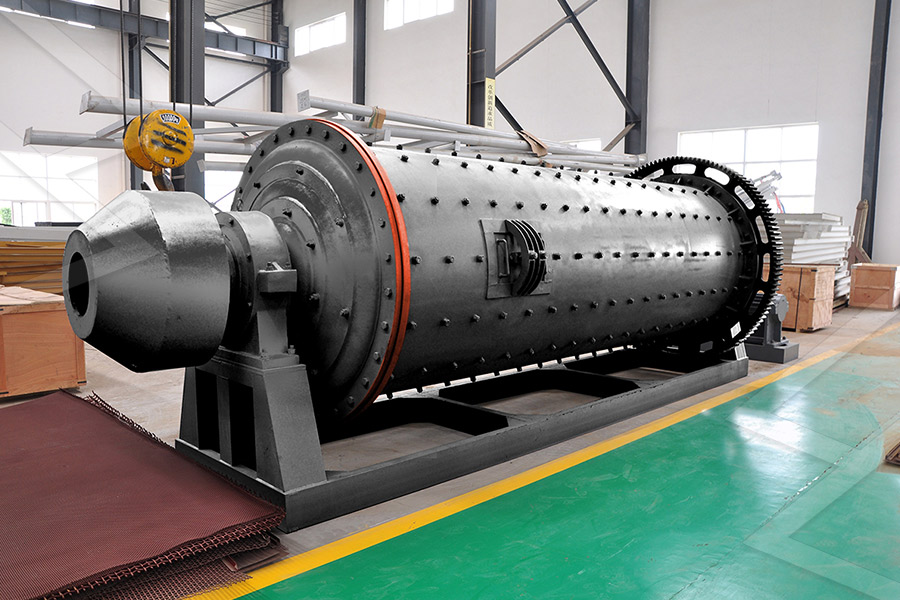

2020年8月27日 — In our previous studies, we investigated the performance of a novel pneumatic planar magnetic separator (PMS) for the dry beneficiation of a selected magnetite ore In the present study, we have extended the studies on the PMS with the focus on investigating how various PMS processing flowsheet configurations influence its 2023年5月12日 — Crush the raw ore to 100mm with a jaw crusher and a roll crusher 2 Washing: Set a trommel screen to remove the muddy impurities in the ore 3 Grinding: Use a ball mill to grind the raw ore to 95%0074mm 4 Magnetic separation: Use a magnetic separator to remove iron impurities in the pulp 5 Flotation:Magnesite Ore Processing: Separation and Calcination2022年8月10日 — processed by Medium Intensity Magnetic Separators (MIMS) • Weak magnetic minerals (generally defined as low susceptibility, para ferri or antiferromagnetic minerals) are processed by HIMS (High Intensity Magnetic Separators) The Metso Outotec HIMS is referred to as HGMS (High Gradient Magnetic Separators) Metso Outotec For dry and wet processing Low Intensity Magnetic 2024年2月8日 — Present investigation includes the magnetizing roasting of lowgrade iron ore fines followed by grinding and beneficiation using magnetic separation The hematite iron ore used in the investigation contains 5317% T Fe, 107% SiO2, and 45% Al2O3 Powdered bituminous coal of 210 μm size with an ash content of 125% and fixed carbon Beneficiation of LowGrade Hematite Iron Ore Fines by

8 Pieces of Gold Mining Equipment to Get Gold Concentrates

2023年5月27日 — Magnetic gold separators are used to remove the high concentration of magnetite recovered with the gold before further processing Therefore, they are efficient recovery machine for gold in iron ore Magnetic separators can recover gold trapped in magnetic black iron sand which can be seen in mining concentrates, tailing piles and on Magnetic Separators that easily separate ferromagnetic and paramagnetic particles – and remove tramp metals – from dry solids or slurries Find out how Multotec Login Wet high intensity magnetic separators from Magnetic Separators Multotec2011年4月1日 — Commercial chromite ore beneficiation processes Pure chromium is difficult to produce since it is readily contaminated by many other elements Huge quantity of raw chromite ore is being mined and beneficiated in various chrome ore beneficiation plants throughout the world to cater the customized needs of various ferro alloy plantsChrome ore beneficiation challenges opportunities – A 2023年9月4日 — The iron ore magnetic separation production line consists of iron ore beneficiation equipment, including Select a gravityseparating machine based on the particle size of the iron ore double roller Iron Ore Beneficiation Plant Equipment For

Magnetic separation: A review of principles, devices, and applications

Abstract: Conventional magnetic separation devices are widely used for the removal of tramp iron from a variety of feed materials and for the beneficiation of ferrous ores These devices for separation of strongly magnetic materials employ a variety of mechanical designs Recently developed high gradient magnetic separation devices extend the 2023年2月15日 — Cassiterite is sent to a magnetic separator to remove magnetic iron and other minerals susceptible to magnetism, such as wolframite Magnetic separators are divided into dry magnetic separators and wet magnetic separators Cassiterite mainly uses wet strong magnetic separation Wet magnetic separators are used to separate The Definitive Guide to Process Cassiterite Fote Machinery2023年4月7日 — Magnetite is the main mineral in iron ore beneficiation, which has industrial value and is mined in large quantities Ftmmachinery recommends a weak magnetic separator and flotation machine for you 3 Magnetization calcination method 1 The classified material flows into the magnetic separator to separate the magnetic mineral How to Recover Iron from Magnetite: 4 Methods and Stages2022年10月27日 — of the material for which magnetic separators are fitted, while smaller magnetic particles, eg, 03–05 mm, are separated less efficiently Therefore, dry beneficiation wastetailingsBeneficiation of Magnetically Separated IronContaining Ore

A Novel Pneumatic Planar Magnetic Separator for Magnetite Beneficiation

2020年8月27日 — A Novel Pneumatic Planar Magnetic Separator for Magnetite Beneficiation: A Focus on Flowsheet Configuration2023年9月28日 — 01 Gold and copper ore heap leaching beneficiation method Heap leaching is a common method for extracting gold from lowgrade goldcopper oresThe ore is crushed and stacked into piles, then impregnated with a solution that dissolves the gold The resulting goldcontaining solution is collected and processed to recover the goldHeap Leaching and Magnetic Separation for GoldCopper Ore Beneficiation 2022年12月2日 — Magnetic Separation: Magnetic separators are employed to separate magnetic minerals from nonmagnetic ones This is particularly useful for removing magnetite or other strongly magnetic minerals from the ore Froth Flotation: Froth flotation is a commonly used method for separating fine particles of minerals In iron ore Everything You Need to Know About Iron Ore Beneficiation2019年1月23日 — In this study, mineralogical analysis and beneficiation experiments were conducted using a placer deposit of North Korea, on which limited information was available, to confirm the feasibility of Separation of Monazite from Placer Deposit by

.jpg)

Bauxite Beneficiation Tailings Reprocessing

5 天之前 — It is mainly used to separate diaspore and kaolinite, and alkaline substances are added to the flotation machine as a medium Magnetic separation process mainly uses a magnetic separator to separate iron The relevance of the paper is that dry magnetic separation (DMS) is the main beneficiation method of magnetite ores The lack of efficient industrialgrade machines and apparatus for separating finegrained magnetite ores means that DMS is used mainly as a preconcentration operation for fairly large classesAssessing the performance of a novel pneumatic magnetic separator 2022年4月24日 — Separation using magnetic separator according to the magnetic difference of minerals Applied material: magnetite, pyrrhotite, calcined ore, ilmenite, etc Gravity Separation Process Gravity beneficiation is separating mineral according to the specific gravity of the material Spiral chute, spiral classifier and shaking table are usually usedOre Beneficiation Plant / CrushGrindExtract/Factory Price2012年7月5日 — Ganzhou Gelin Mining Machinery Co, Ltd is an over 30 years professional manufacturer and exporter of mining machinery for crushing, screening, grinding, flotation, magnetic/gravity separation etc in Chinathe machines are excellent for processing gold,diamond,iron ore, ilmenite, manganese ore etc Gelin have a complete service Ilmenite Ore Separate Machine Weak Magnetites Separation

Application of Magnetic Separation Technology in Resource

2024年4月24日 — Magnetic separation technology is a physical separation method that uses the differences in magnetism between matter to separate them from each other by different motion behaviors in a nonuniform magnetic field It is highly efficient, green, and environmentally friendly, with little change in the physical and chemical properties of raw 3 天之前 — Materials over 5mm are sieved and returned to the doubleroll crusher for further processing Those under the sieve under 5mm material are sent to the first and second magnetic separators 5 The output from the first and second magnetic separators will be sent to the third magnetic separator to separate the iron ore again Finally, the iron Iron Ore Beneficiation Plant JXSC Machinery2018年2月5日 — Progressing Field Magnetic Separator Description This is a dry magnetic ore separator on which liberated minerals of a pulverized ore are concentrated by a highfrequency vibrating deck and by a progressing magnetic field It is designed to separate particles according to their magnetic susceptibility, size, and shapeElectrostatic Magnetic Separators 911Metallurgist2024年4月11日 — In view of the current development and utilization of complex and difficulttoseparate magnetite ore resources, selecting appropriate mineral processing equipment and appropriately improving the beneficiation process are important ways to improve the efficiency of iron ore beneficiation Magnetite ore separation equipment is classified Single Mineral Processing Machines for Magnetite Ore Xinhai

.jpg)

Your iron ore beneficiation solutions Downer Group Site

2017年10月24日 — Where the ore is different and challenging, we bring innovative capabilities to design new and unique solutions that augment and lift the potential of conventional flowsheets to extract the ore Plant Design Extending beyond traditional spiral plants our designs incorporate gravity, magnetic and electrostatic beneficiation 2020年3月20日 — The relevance of the paper is that dry magnetic separation (DMS) is the main beneficiation method of magnetite ores The lack of efficient industrialgrade machines and apparatus for separating finegrained magnetite ores means that DMS is used mainly as a preconcentration operation for fairly large classes The aim of the research is to study DRY MAGNETIC SEPARATION OF MAGNETITE ORES2024年9月7日 — Our factory professional produce different type Magnetoelectric Separator over 30 years The products includes dry type magnetic separator, wet type magnetic separator, electrostatic separator 40200tph Mine Ore Mineral Beneficiation Plant 2020年9月1日 — In another study, Ezhov and Shvaljov (2015) used a laboratoryscale EVS10/5 magnetic separator for dry beneficiation of iron ore of the Backer deposit This was done by analysing the influence of the current strength in the electromagnet winding of the magnetic separator on concentrate yield and recoveryAssessing the performance of a novel pneumatic magnetic separator for

.jpg)

Five Kinds Technology Of Manganese Ore Beneficiation

5 天之前 — Manganese ore magnetic separation is widely used to separate valuable from gangue minerals It uses the magnetic differences between various minerals to separate them Applying a magnetic field to a mixture of ore and gangue minerals attracts magnetic particles to the area, while nonmagnetic particles are repelled or pass through unaffected2024年9月22日 — Automatic Magnetic Flotation Separators Iron Ore Beneficiation LONGi's Automatic Magnetic Floatation Separators have been been found to be able to regularly upgrade the grade of, some concentrates, by a factor of 29% greatly upgrading the quality of the end product This makes for a highly efficient and inexpensive way to upgrade your Automatic Magnetic Flotation Separators Iron Ore Beneficiation5 天之前 — Sometimes there are many iron impurities, in order to reduce the content of iron impurities, the magnetic separation method can be used for treatment The magnetic separation equipment is a permanent magnetic drum magnetic separator, a wet strong magnetic plate magnetic separator, and a vertical ring high gradient magnetic separatorProgress of Five Spodumene Beneficiation Methods JXSC MachineryMagnetic separation is a beneficiation method that uses the magnetic difference between minerals in a nonuniform magnetic field to separate different minerals Magnetic separation is the most commonly used beneficiation method for ferrous metal ore such as iron ore It is divided into weak magnetic separation and strong magnetic separation Process and Principle of Magnetic Separation of Iron Ore

.jpg)

Guide of Mineral Processing Methods: 3 Main Beneficiation

2021年6月11日 — Mineral processing methods are mainly divided into two categories, namely physical mineral processing and chemical mineral processing Physical Mineral Processing Physical beneficiation includes magnetic separation, gravity separation, electrostatic beneficiation, friction beneficiation, particle size beneficiation, shape beneficiation, 2023年3月9日 — Magnetic separators are widely used in the beneficiation of ferrous metal ores, nonferrous and rare metal ores; the recovery and purification of media in heavy media beneficiation; the removal of impurities from nonmetallic ore raw materials; the removal of ironcontaining impurities in crushing; recycling scrap steel from smelting waste residue Magnetic Separators For Mineral Processing JXSC Mining